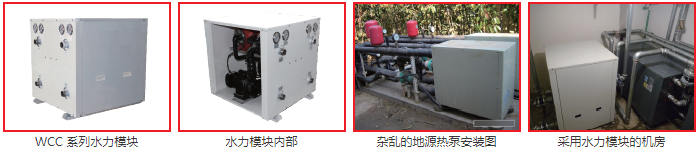

The ground source heat pump hydraulic module solves the shortcomings of the traditional unit, which covers a large area, is not beautiful, loud noise, long construction period, and the construction quality is not easy to control, and provides customers with a compact, beautiful and low noise machine room environment, which is what customers want.

User profile

▶ Small ground source heat pump is mainly used in villas and senior apartments, because the ground source heat pump has cooling water and frozen water loop, for the unit with heat recovery function and hot water loop, each loop needs a pump, which needs to solve the water expansion, pressure ultra-high pressure relief, flow protection and other pipeline components.

▶ Villas and senior apartments are very hope that the indoor and outdoor environment is beautiful, the air conditioning room clean and beautiful and noise requirements are very high.

▶ There is no professional manager for the air conditioning unit, and the machine room is in the basement or balcony of the owner, with a relatively small area and high requirements for the aesthetics of the pipeline direction.

Disadvantages of the existing ground source heat pump room

▶ It is usually installed by the installation personnel on the site of the water pump, expansion tank, water flow switch and other components, the construction period is long, the construction cost is large, and the construction quality is difficult to control, which is related to the quality and experience of the construction personnel.

▶ Water pump and other components occupy a large amount of room area, and it is not beautiful.

▶ Because it is impossible to isolate the noise of the pump operation, the noise of the entire machine room is relatively large.

Advantages of hydraulic module room

▶ The hydraulic module adopts three-dimensional ultra-thin design, which can superposition the ground source heat pump host and the hydraulic module. In order to facilitate maintenance, the total height of superposition is controlled within 1.5 meters. This ultra-thin product design is the perfect presentation of ACOL's "everything for the customer" product design concept, which is 40% less than the traditional hydraulic module height, so that customers not only save floor space but also save room space.

▶ The hydraulic module is equipped with pump group, valve group, automatic water refill, safety components, optional by-pass components, optional system cleaning and sewage components and control components, etc., and all do cold, heat preservation, sound insulation treatment and strict inspection before leaving the factory.

▶ Using the hydraulic system modular integrated design scheme, it is a completely prefabricated complete set of products under strict monitoring and production. The hydraulic module is beautiful, energy saving and environmental protection, saving time and investment, improving the quality of the project at the same time, but also flexible use, quick installation and other characteristics, is the best choice for ground source heat pump system.

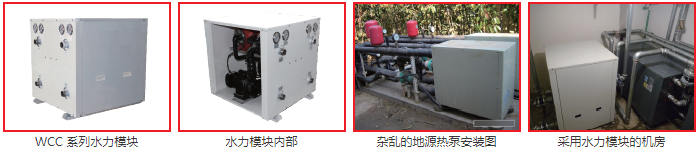

Hydraulic module room solution application

▶ In 2009, we proposed a hydraulic module solution, which completely solved the messy pipelines of previous ground source heat pump projects, and helped villa developers or owners to reduce the area of the computer room, and these savings in the area of the computer room were given more value. Due to our hydraulic module built-in precise flow protection switch, differential pressure bypass control, independent automatic water supply and constant pressure system, pipeline material is made of stainless steel pipeline, really achieve user convenience and maintenance free, so stand on the customer's point of view design of hydraulic module by developers, more than thousands of ground source heat pump used this program.